In the bustling world of eyewear, Dr. GRAM stands out as a beacon of uniqueness at Malaya Optical Kuala Lumpur. Renowned for its distinctive design philosophy and commitment to quality, they carved a niche for itself, offering customers an unparalleled blend of style and functionality.

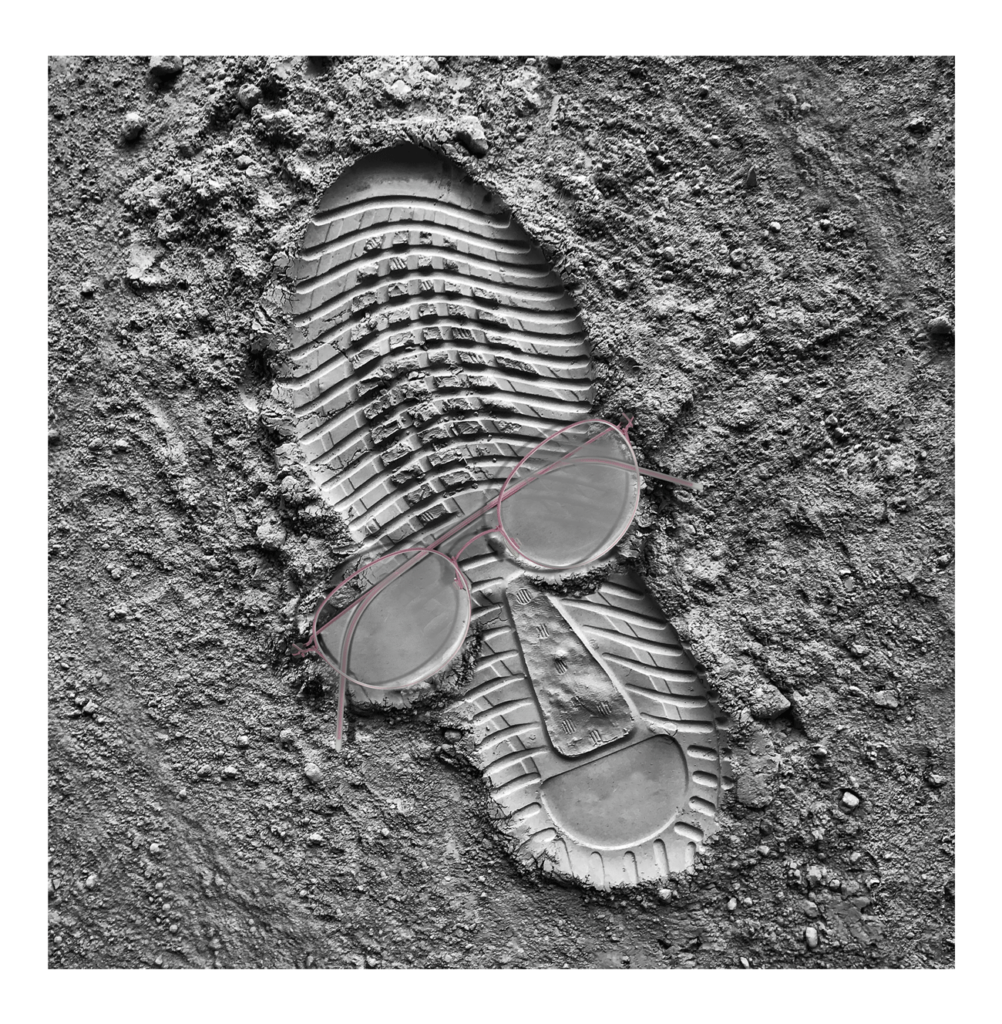

Dr. GRAM eyewear are comfortable, eco-friendly and extremely light, beta-titanium glasses frames. It weighs only 3 grams, lighter than a piece of A4 printing paper and features a unique fabric weaving hinge structure that do not require screws or welding.

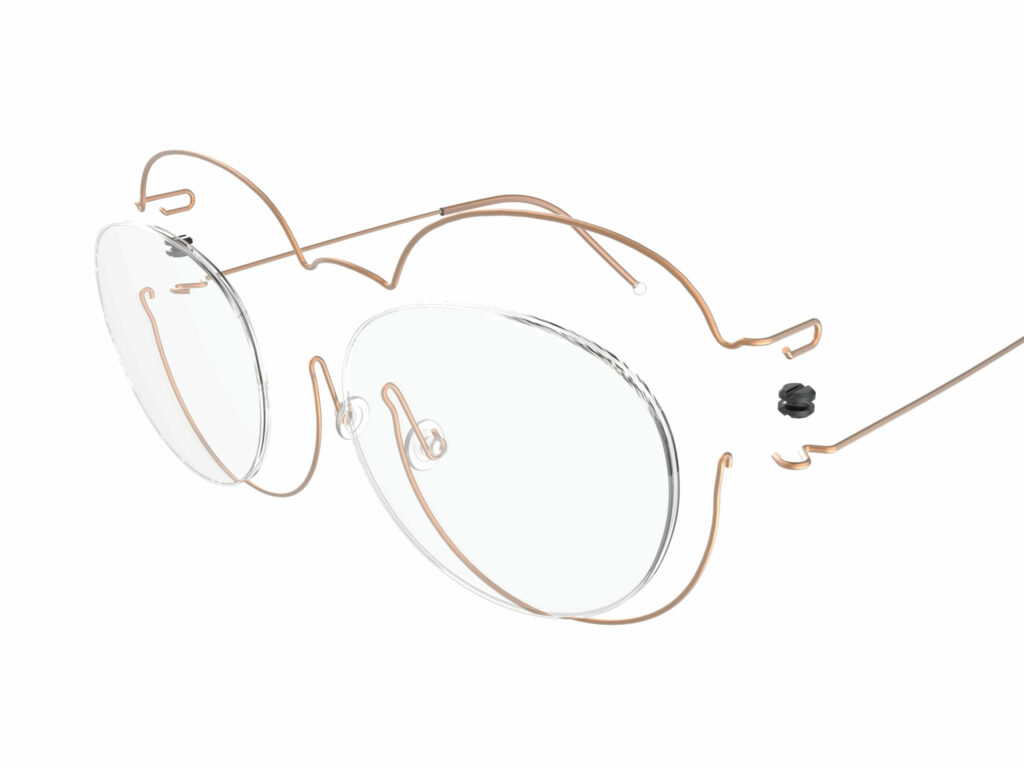

Dr. GRAM focusses three factors in its design: ensuring the zero loss of titanium material during production, eliminating screws and welding to reduce errors and weight, and simplifying the manufacturing process. On average, 70% of the titanium plate is discarded in traditional eyewear production since titanium plates are not reusable, but Dr. GRAM optimizes material use by weaving titanium wires (0.8mm diameter) into wire frames instead of cutting out the frames from titanium plates. Eliminating the need for screws and welding also reduces the risk of failures and defects that would contribute to invisible waste. Lastly, by simplifying the manufacturing process, it allows for better efficiency and productivity in the end-to-end process.

Dr. GRAM’s eyewear gains efficiency not only from optimizing raw material usage, but also from a 3-stage production method of process isolation. This allows glasses to be manufactured with higher durability while reducing the complexity for repairs.

β-titanium Frame

Beta-titanium has been used in many industries such as spacecraft, aircraft, and military applications because it has very high tensile strength and toughness with super lightweight. Dr. GRAM is supreme: 100% beta-titanium and ergonomically designed with bendable arms and flexible fit, which provides fantastic comfort for hours on end.

Beta titanium is a very flexible, ultra-light material that is human-friendly, strong and durable. These characteristics make it used in many high-value industries, and Dr. GRAM frames made entirely of beta titanium provide fantastic comfort to your face.

Endurance

As beta-titanium has extraordinary corrosion resistance and can withstand extreme temperatures, many companies have used it as highly stressed components such as connecting rods on expensive sports cars and premium sports equipment. Dr. GRAM have been using beta-titanium for every component of their glasses to offer an outstanding experience to the customers.

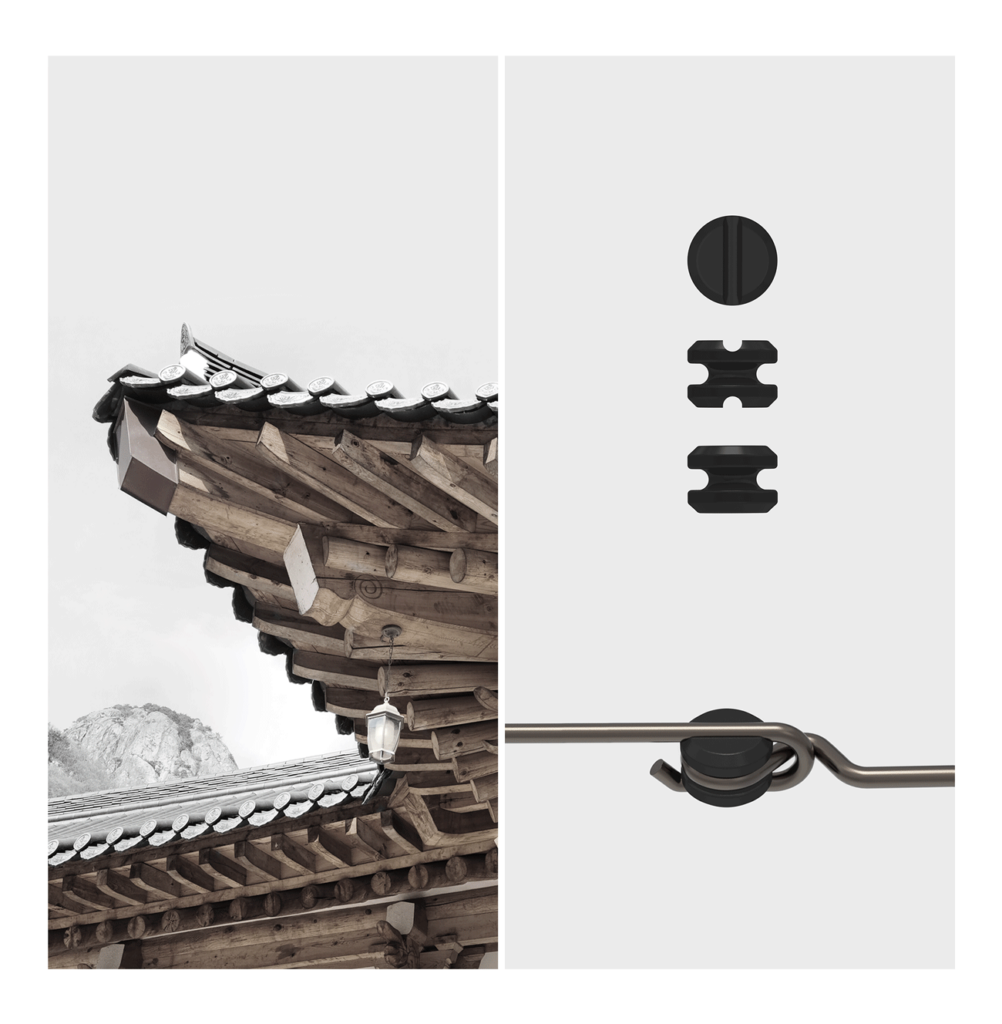

Original Hinge

With the beautiful hinge design, you don’t need any screws or rivets to connect the eyeglass hinges to their frames. Dr. GRAM’s unique hinge patented hinge structure has already won awards at Red Dot and IF, the world’s top three design awards, and has been recognized as a unique design. The hinges, which are manufactured without any screws, rivets, or welding, do not become loose even after long-term use, and are Dr. GRAM’s unique identity.

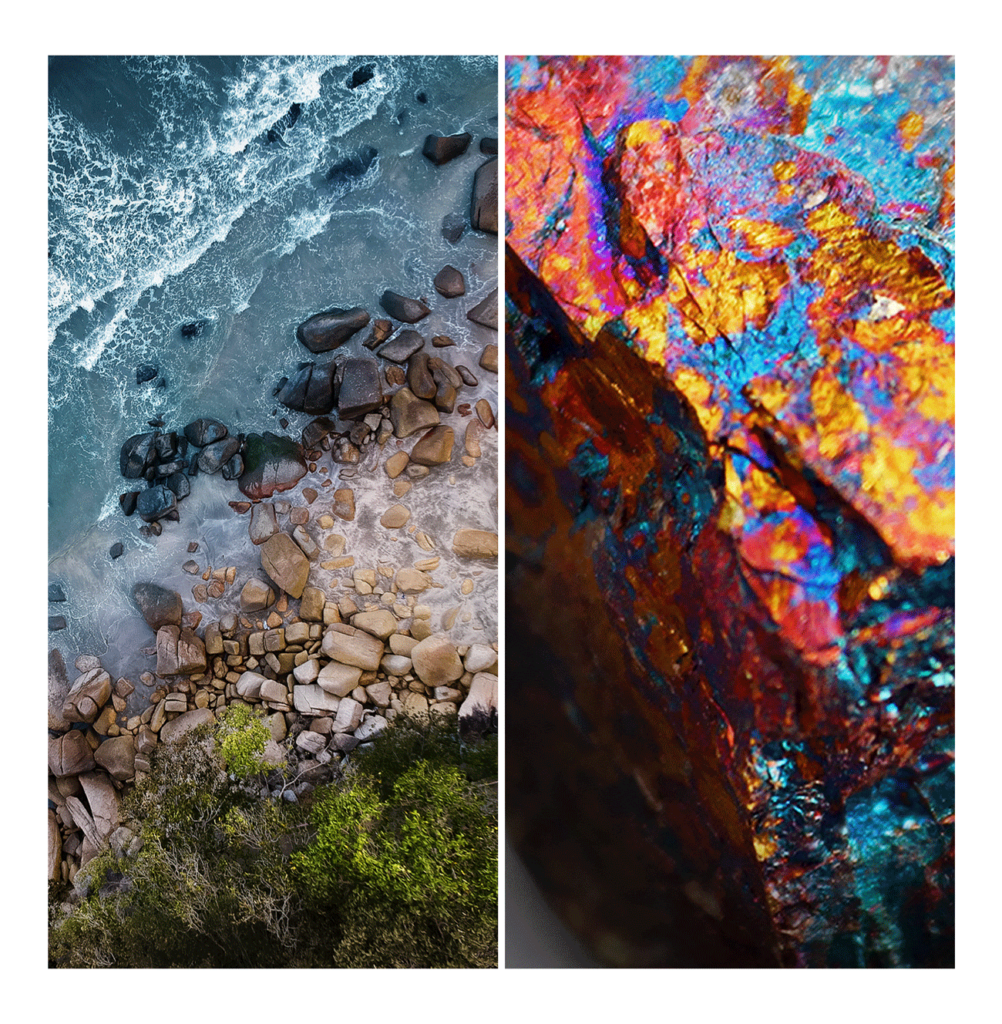

Titanium Color

Titanium oxide films are then used to apply various colors to different parts of the glasses. These parts can be assembled to create customized eyewear. Without using chemical dye, the colors are applied to titanium using an electric current that generates an oxide film on the surface. Oxide films, unlike typical color coating technology, help preserve the density and sturdiness of the eyewear structure, and has a more negligible impact on the environment.

” We used unprecedented color process technology called Oxide Film. This technology allows you to express unique brilliant colors which you have never seen before. ”

Ready to elevate your eyewear game to the next level? Look no further than Malaya Optical Kuala Lumpur, where style meets vision! Our shelves are brimming with the latest designer and branded eyewear collections that will make heads turn and eyes sparkle. Book an appointment with us now!